it had been week plus since last update, quite lots of work done by me and my mech in this duration... let the pics and stories begin

the mech actually quite sien with the bearing fitting already, he not only change the conrod bearing and test with plastic gauge to get the best clearance, but took out independent rods and piston and put to different bore and test, but result still disappointing, the 2nd conrod bearing still shows unbalances clearance and over wide clearance.. so he stop after switch the rods and piston with another bore.. then, i saw he no work, then i tangan gatal go take all the tools he used and do what he do,put plastic gauge and torque to spec with torque wrench.. magically, this is the result.

seems like my engine like me to touch it

ok, the 1 week headache problem solved, now the mech start to reassemble things back... first the oil sump parts

then putting in the ARP "piling"

then the head is in, with arp , it actually required special size and special tools,we all thought it is a 13mm nuts so i gound a short socket to use, howver, during the torque process (torque according to oem manual,70nm > 0 > 20nm > 90 degree x 2) , the socket slide off twice and hurt the nut little, and then we figure out the socket is too short and keep obstructed by other stuff in the head so cant have a tight fit.. and also my fren(a mech and experience in motorsport) tole me it is "angmo size" 1/2 not 13mm.. so i rush to buy a long socket sized 1/2.. then they finally torque it down properly

sun up sun down, another day, today i feel free to brush and spray black my oil sump, but sorry no actual pic of it.. so i just put my oil sump pic, and i do discover mitsubishi really do effort on their engine, it come originally a buffered oil sump... and it remind me once upon a time how hard i search for buffer plates for my honda engines

then i took all the cams and trinity clutch to be rdy to install(no budget so use cheap clutch

),meanwhile, a new water pump is installed

then the mech install the cams and cam pulleys, same, bearing caps torque to specs then turn using hand to test for smooth turning (lifter and rocker arm not installed)

when mech thought all run smoothly, then something weird happen, when wanna install timing belt, discovered the 1st piston stuck with valve ,why?? all according to the campulley and crank mark.... we all no answer, i thought i got fake pulley or the crank gear timing mark gone wrong, then again i ask for help from my fren that pro in motorsport since his workshop beside only

once he came here and see, one funny and simple mistake occur, intake and exhaust cam installed terbalik

but we had install according to the sticker stick on the package, which mean the supplier opened the package and put back wrongly

nvm, we redo the all progress again, then everything done...

then the engine's part mostly done with the timing belt installed...

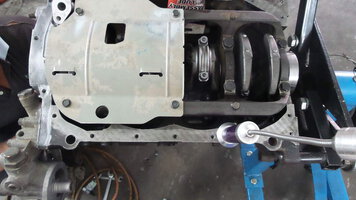

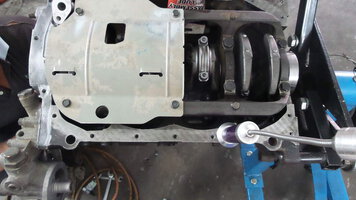

then it is the transmission, but it is quite simple, new trinity clutch kit, new clutch bearing,stick the gearbox in, done... some thing hard to do is that we forgot we need install the middle cross member first before install back the mid differential, we think of other way round, nvm, same thing, re do it again

....now the engine with all things are in the engine bay again,wait all other parts installed back,maybe i can finally hear the engine sound i did not heard for months next week:rolleyes:

(actually more things already in the engine bay but i forgot to take the pic) .. however, i still need find new engine side engine mount cause i found all other three mounts but not that one here (pity kampung area people)

it almost done,stay tuned

with this it ease a lot of the cams adjustment since my mech got all the specs written down on how to tune the cams with ori hks pulley.... can simply dial in without degree wheels

with this it ease a lot of the cams adjustment since my mech got all the specs written down on how to tune the cams with ori hks pulley.... can simply dial in without degree wheels

),meanwhile, a new water pump is installed

),meanwhile, a new water pump is installed

once he came here and see, one funny and simple mistake occur, intake and exhaust cam installed terbalik

once he came here and see, one funny and simple mistake occur, intake and exhaust cam installed terbalik

but we had install according to the sticker stick on the package, which mean the supplier opened the package and put back wrongly

but we had install according to the sticker stick on the package, which mean the supplier opened the package and put back wrongly nvm, we redo the all progress again, then everything done...

nvm, we redo the all progress again, then everything done...

....now the engine with all things are in the engine bay again,wait all other parts installed back,maybe i can finally hear the engine sound i did not heard for months next week:rolleyes:

....now the engine with all things are in the engine bay again,wait all other parts installed back,maybe i can finally hear the engine sound i did not heard for months next week:rolleyes: (actually more things already in the engine bay but i forgot to take the pic) .. however, i still need find new engine side engine mount cause i found all other three mounts but not that one here (pity kampung area people)

(actually more things already in the engine bay but i forgot to take the pic) .. however, i still need find new engine side engine mount cause i found all other three mounts but not that one here (pity kampung area people)