- Joined

- Apr 18, 2006

- Messages

- 3,677

- Points

- 1,663

Well, all these adds up to experience.

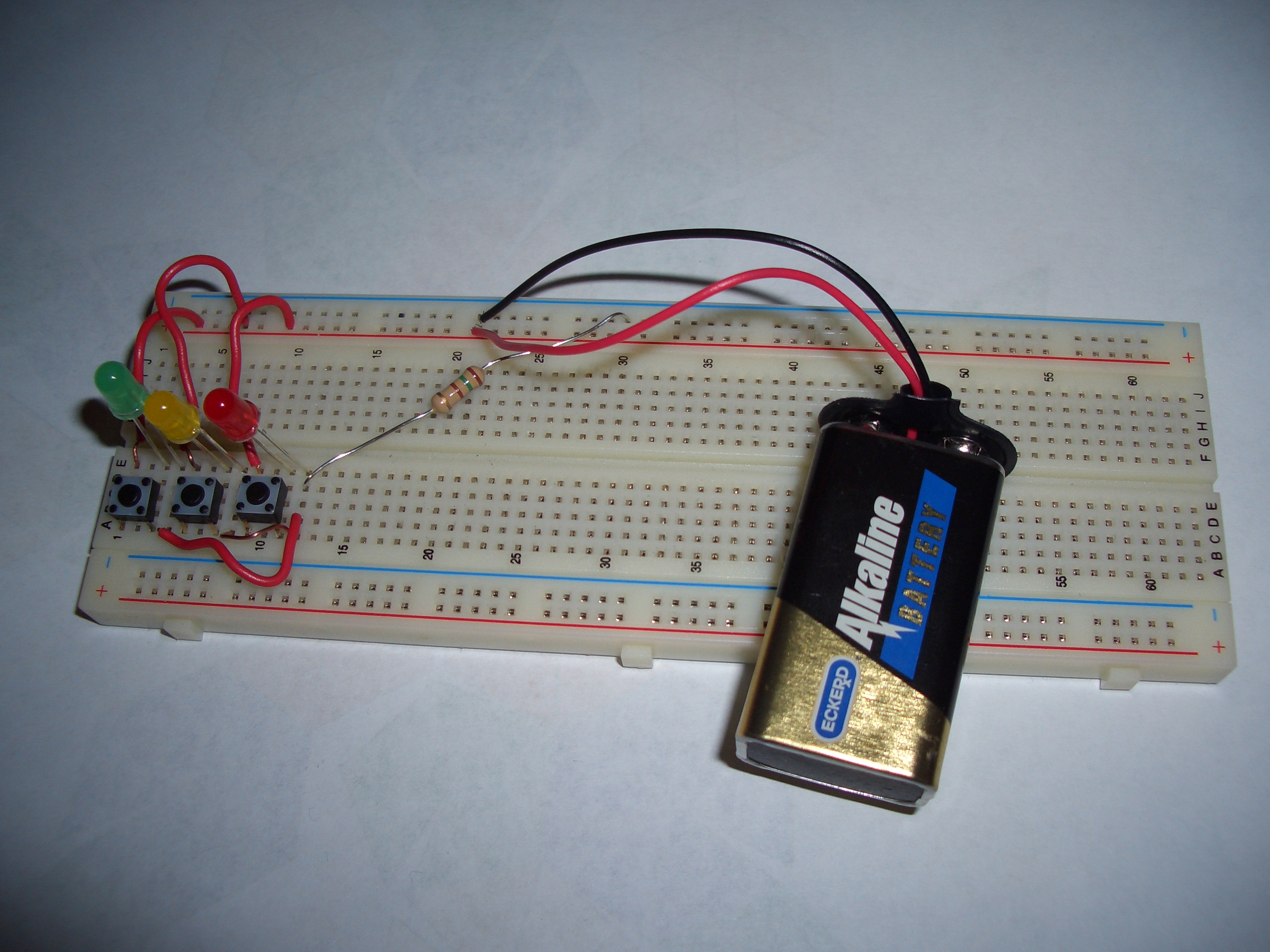

Btw, breadboard is plastic too right? Can it withstand the solder heat?

And plus, i just started to learn how to solder, i had a few cold solder. Bad.

you don't solder on breadboard.

a soldering aid like the soldering helper with arms are cheap rm20ish only and is a good buy if you solder often.

solder iron wattage also important. I use a 60-100w for car wires that are thick, and 25-40w for components.

Sent from my GT-I9100G using Tapatalk 2